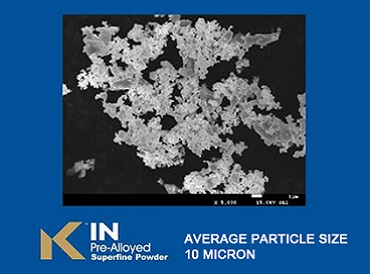

Superfine Pre-alloyed Powder

We supply a series of iron base superfine pre-alloyed powders, such as Fe-P, Fe-Ni, Fe-Cu-Sn, Fe-Cu-P, Fe-Cu-Ni-Sn, Fe-Zn for many applications in a wide range of industries: diamond tools, electronic components, powder metallurgy, magnetic materials, wave absorbing & shielding materials, new composite materials

Characteristics

Made by chemical way

Made by chemical way Laser particle size of 3~10 um

Laser particle size of 3~10 um Similar like spherical particles

Similar like spherical particles Homogeneous particles & components

Homogeneous particles & components Excellent compaction & sintering properties

Excellent compaction & sintering properties Low oxide pre-alloyed powders

Low oxide pre-alloyed powders Stable & repetitive batch production

Stable & repetitive batch production

Pre-alloyed Powder Series

Here only shows our regular series products, feel free to contact us for more product information.

| Composition | Grade | D50(μm) | Hardness(HRB) |

|---|---|---|---|

| Fe-Cu-Sn-Ni | SFN-10 | 5.2-8.5 | 95-110 |

| Fe-Cu-Sn-Ni-P | Kind4-1234 | 5.2-8.5 | 95-110 |

| SHN-01 | 3.0-5.0 | 95-105 | |

| Fe-Ni | Kind2-1318 | 4.5-6.0 | 85-105 |

| SFN-01 | 3.0-5.5 | 85-95 | |

| SFN-02 | 8.0-12.0 | 95-105 | |

| SFN-06 | 3.8-7.2 | 95-105 | |

| Fe-Zn | SUZ-01 | 22.0-28.0 | 95-102 |

| SUZ-03 | 25.0-35.0 | 105±3 | |

| SUZ-50 | 12.0-18.0 | ||

| Fe-Cu-Sn | SCF-07 | 4.5-8.0 | 95-110 |

| KIN-04B | 12.0-18.0 | 95-105 | |

| Fe-Cu-Sn-P | SCF-11 | 4.5-8.0 | 80-90 |

| SCF-12 | 22.0-28.0 | 95-105 | |

| Fe-Cu-Zn-Sn-P | SCF-10B | 22.0-28.0 | 100±5 |

| Fe-Cu-Zn-Sn-Ni-P | SCF-10B+ | 15.0-25.0 | 105±5 |

Medium and High Grade Pre-alloyed Powder

| Grade | Composition | D50(μm) | Hardness(HRB) |

|---|---|---|---|

| KIN-01 | Cu-Co-Sn-Zn | 8.0-15.0 | 84-90 |

| KIN-05 | Fe-Cu-Co-Ni-WC. | 3.5-5.5 | 105-110 |

| KIN-05B | Fe-Cu-Co-Ni-Sn-W | 4.0-8.0 | 100-110 |

| KIN-06C | Fe-Cu-Co-Sn-P | 5.5-8.0 | 95-105 |

| KIN-10 | Fe-Cu-Co | 8.0-15.0 | 85-95 |

| KIN-15 | Fe-Cu-Co-Ni | 3.0-4.5 | 104-107 |

Pre-alloyed Powder For Diamond Tools

Micron grade series of superfine pre-allloyed powder produced by chemical way is with tiny laser particle size of 3~10um, homogeneous particle size, good cold press molding, good wear resistance, high sintering activity, broad scope for application temperature(700~900°C).

In the adaptive temperature range, the sintered matrix has good structural homogeneity and density, and the sintering hardness is 85~100 HRB, the bending strength is more than 1000 MPa.

The prominent characteristics of our powder are good comprehensive mechanical performance and wide application, which is suitable for making high-grade granite cutting & grinding tools, saw blades, engineering drill bit, ceramic cutting & grinding tools, etc.

Click here to know more about pre-alloyed powder for diamond tools

Have some questions?

How can I get the datasheet or know the price?

Please send email to [email protected] or go to the contact us page and you'll find a feedback form.

Can we get technical advice?

Of course yes. SAGWELL has more than 20 years experience in micro & nano metal powder materials, our technical team are ready to answer any questions you have.

If you are not sure which product is the best for you, we'll recommend the corresponding products for your needs.

Can I get a sample for testing?

Yes, we offer free small sample for testing, feel free to contact us.